Reinforcement and Core Materials

Composites are made up of individual materials referred to as constituent materials. There are two categories of constituent materials: matrix (polyester, vinyl ester or epoxy resin) and reinforcement. The matrix material surrounds and supports the reinforcement materials by maintaining their relative positions. The reinforcements impart their special high mechanical strength values and improve values of composite structure.

Reinforcement and Core Materials

Composites are made up of individual materials referred to as constituent materials. There are two categories of constituent materials: matrix (polyester, vinyl ester or epoxy resin) and reinforcement. The matrix material surrounds and supports the reinforcement materials by maintaining their relative positions. The reinforcements impart their special high mechanical strength values and improve values of composite structure.

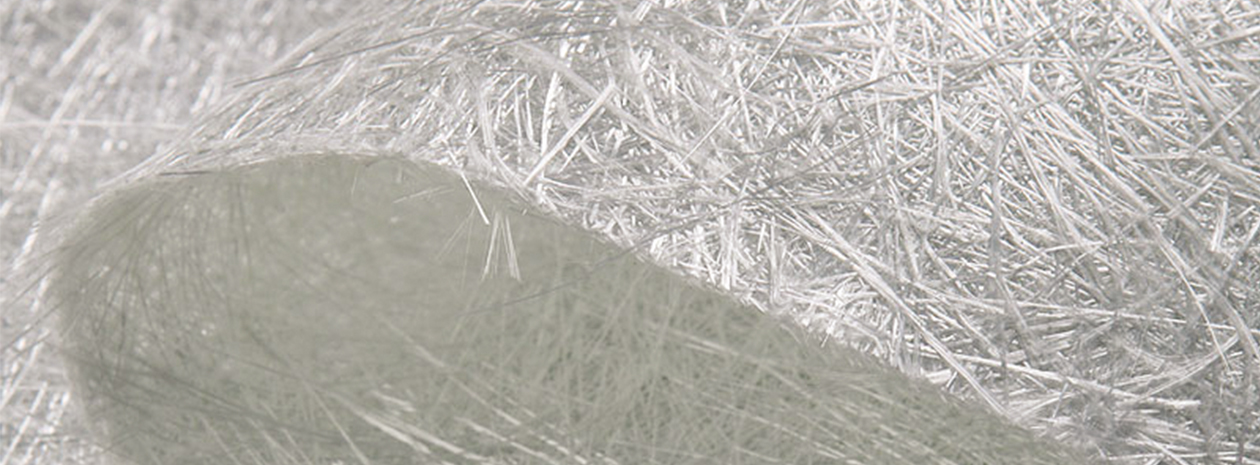

Chopped Strand Mat

E-glass CSM is the most widely used polyester and vinyl ester resin reinforcement for HLU. Strands of glass fiber are held together by an emulsion or powder binder to form a mat.

Polyester resin dissolves the binder allowing the fibers to follow the mold contours. A typical FRP tructure would contain approx. 2,5 kg resin to 1 kg CSM.

Emulsion Bound:

E-glass E-MAT1 300,450,600gr/m2

Powder Bond:

E-glass MAT-8 300,450,600gr/m2

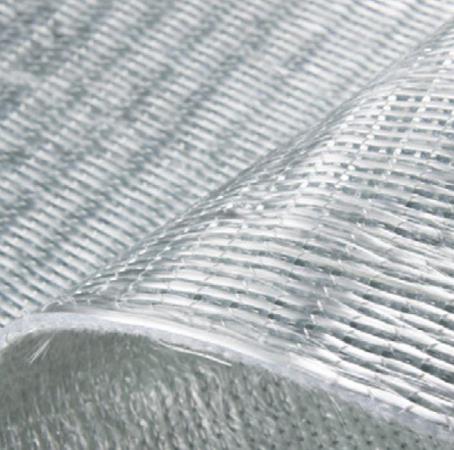

Fiber Woven Roving

E-glass roving is a bi-directional fabric made by interweaving direct rovings. It is for laminating large fiberglass parts where a cost effective, high impact, high strength reinforcement is required. It is often used for boats and tanks in conjunction with CSM as a simple means of adding bulk to increase stiffness. A typical laminate use approx. 1 kg resin to 1 kg FWR.

FWR:

E-glass 300,500,800gr/m2

Spray-up Roving

E-glass assembled rovings are compa tible with polyester and vinyl ester. It’s used for spray-up. KCR2/KCR3 are recommended for spray-up applications.

Spray-up Roving: KCR2/KCR3

Direct Roving

E-glass assembled rovings are compatible with polyester and vinyl ester. It’s used for filament winding and pultrusion processes or weaving. KCR5 for pipe productions, PWR6 for filament winding and pultrusion productions.

Direct Roving: KCR5/PWR6

RTM Mat

Reinforcement complex consists of a resin liner core sandwiched between chopped glass fiber and mechanically stitched together. It’s ideal reinforcement for molding GRP parts using closed mold techniques including RTM, RTM light, low-pressure compression, infusion with built-in resin flow zones. Check our website for more information.

RTM Mat types include:

200M / 180PP / 200M

450M / 250PP / 450M

600M / 250PP / 600M

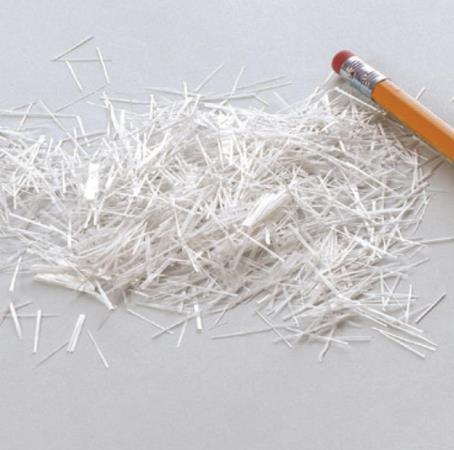

Chopped Strands

Chopped fiberglass strands are glass fiber strands that can be mixed to resin or concrete to make a dough like mixture which is extremely strong. This coarse mixture is used to strengthen castings and reinforce fillers in difficult to laminate areas such as sharp internal corners.

Surface Tissue

This material is a thin fiberglass fabric which is used between the gelcoat and the reinforcing materials. Surface mat is similarly manufactured and has a similar appearance to the chopped strand mat but it is much finer.

This surfacing veil prevents the weave patterns from bleeding through the gelcoat. Also, it is used to provide a resin-rich layer in liquid or chemical holding tanks or reinforcement for layers of gelcoat.

Weights: 14 gr/m2 and 43 gr/m2.

Multiaxials

High performance multiaxial reinforcements are engineered fabrics consisting of one or more layers of unidirectional fibers. These layers are held in place by a non-structural stitching thread which is generally a polyester yarn.

Multiaxial types include:

Unidirectional, Biaxial, Triaxial, Quadraxial, Combi Mat, Stitched Mat

Material:

Available in E-glass, Aramid, Carbon, and Hybrid forms.

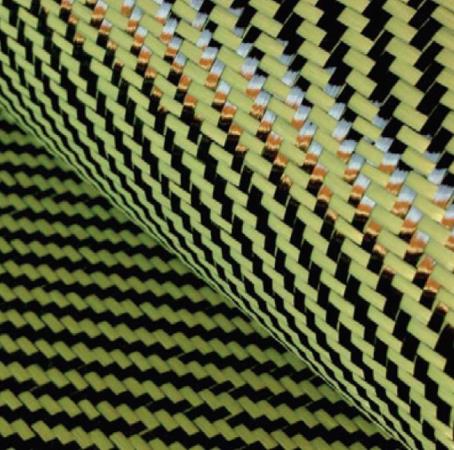

Carbon and Aramid Reinforcements

A high performance reinforcement allowing for better strength to weight ratio than glass fiber. Woven Aramid Fabric exhibits high abrasion resistance. It can reduce weight up to 40% compared to glass.

Polyester resins can be used but, for better performance, vinyl ester or epoxy resin should be used.

Lantor Coremat

This is a non-woven core material and print through barrier for hand lay-up and spray-up processes. It is used to reduce weight, save resin glass, increase stiffness, increase thickness build-up and improve surface finish.

Lantor Soric

Soric is a polyester non-woven material with a compression resistant, hexagonal (XF, SF, LRC) or random dot-printed (TF) cell structure. These pressure-resistant cells, which are separated by channels, contain synthetic micro-spheres.

Cells within the structure do not absorb resin and controls total volume of resin used. Since these cells are pressure resistant, they create thickness in the laminate even when pressure is applied by a vacuum bag.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored