Hand lay-up and Spray-up

Hand lay-up and Spray-up

Prefabricated Buildings

Automotive Parts

Swimming Pool

Bath Pubs

Fiberglass Balustrades

Fiberglass Facade and Cornice

- Product Description

- Chemical Structure

- Available Modifications

- Viscosity

- Thixotropy

-

Monomer Content

-

Gel Time

-

Tmax

-

Tensile Strength

-

Elongation at Break, Tensile

-

Flexural Strength

-

HDT [0,45 MPa]

-

Barcol Hardness, 934

-

Volumetric Shrink

- Remarks

- Highlights

- Primary Usages

-

Polipol 3401

Lloyd's - Hand lay-up / Spray-up polyester

- Ortho

-

- 500-600

- N/A

- 37-41

- 8-14

- 170

- 71

- 2,6

- 134

- 66

- 40

- 7,4

-

OT1 , OT3 - - Quick

and easy fiber wet-out

- Low volumetric shrinkage

- Optimum performance price ratio

Lloyd's Register approved

- Bumpers, fenders, cabinets, pool filters, industrial GRP parts such as vehicle parts.

-

Polipol 3404

New - CHand lay-up / Spray-up polyester

- Ortho

-

- 550-650

- N/A

- 36-38

- 10-12

- 170

- 71

- 3,4

- 134

- 62

- 40

- 7,4

-

OT1 , OT3 - - Quick

and easy fiber wet-out

- Low volumetric shrinkage

- Industrial GRP parts

- Bumpers, fenders, cabinets, pool filters, industrial GRP parts such as vehicle parts.

-

Polipol 3401

Lloyd's

TA-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated polyester

- Ortho

-

- 500-700

- Thixotropic

- 45-50

- (18-22) / (38-42)

- 145

- 71

- 2,6

- 134

- 66

- 40

- 7,4

-

OT1 , OT4 - - No

sagging on vertical surfaces

- Quick and easy fiber wet-out

- Paraffin free

- Peroxide indicator

Lloyd's Register approved

Rapid barcol development

- Bumpers, fenders, cabinets, pool filters, industrial GRP parts such as vehicle parts.

-

Polipol 3401

Lloyd's

TA-LSE-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated LSE polyester

- Ortho

-

- 400-700

- Thixotropic

- 43-53

- (18-22) / (38-42)

- 140

- 71

- 2,6

- 134

- 66

- 40

- 7,4

-

OT1 , OT4 - - Low

styrene emission

- No sagging on vertical surfaces.

- Quick and easy fiber wet-out

Lloyd's Register approved

- Bumpers, fenders, cabinets, pool filters, industrial GRP parts such as vehicle parts.

-

Polipol 3404

New

TA-H20/H40 - GRP type thixotropic preaccelerated polyester resin

- Ortho

-

- 550-650

- Thixotropic

- 43-47

- (18-22) / (38-42)

- 175

- 71

- 3,4

- 134

- 62

- 40

- 7,4

-

OT1 , OT4 - - No

sagging on vertical surfaces

- Quick and easy fiber wet-out

- Parafin free

- Peroxide indicator

- Lloyd's Register approved

- Rapid barcol development

- Bumpers, fenders, cabinets, pool filters, industrial GRP parts such as vehicle parts.

-

Polipol 3404

New

TA-LSE-H20/H40 - GRP type thixotropic preaccelerated LSE polyester resin

- Ortho

-

- 500-700

- Thixotropic

- 44-48

- (18-22) / (38-42)

- 140

- 61

- 3,0

- 120

- 61

- 41

- 7,8

-

OT1 , OT4 - - Low

styrene emission

- No sagging on vertical surfaces

- Quick and easy fiber wet-out

- Lloyd's Register approved

- Bumpers, fenders, cabinets, pool filters, industrial GRP parts such as vehicle parts.

-

Polipol 3880

TA-LSE-H20/H40 - Terephtalic polyester

- Terephthalic

-

- 300-400

- Thixotropic

- 39-42

- (18-22) / (38-42)

- 190

- 70

- 2,9

- 135

- 102

- 48

- 8,0

-

OT1 , OT2 - - High

HDT value

- Excellent mechanical and thermal values

- High modulus and elongation at break value

- As a general purpose resin with mechanical values It is ideal for automotive industry, boat manufacturing, modular cabin and many applications

-

Polipol 3877

New

TA-H20/H40 - rPET-thixotropic preaccelerated terephthalic polyester

- rPET Terephthalic

-

- 500-600

- Thixotropic

- 43-47

- (18-22) / (38-42)

- 190

- 71

- 3,4

- 145

- 81

- 42

- 7,8

-

OT1 , OT4 - -

Excellent fiber wet-out

- Good mechanical properties

- Optimum HDT

- Paraffine-Free

- No sagging on vertical surfaces - AC units and system components, applications which require mechanical strength such as GRP parts for marine and automotive industry.

-

Polipol 339

TA-LSE-H20/H40 - Hand lay-up / Spray-up medium reactivity thixotropic preaccelerated LSE polyester

- Ortho

-

- 600-800

- Thixotropic

- 41-44

- (18-22) / (38-42)

- 180

- 68

- 2,2

- 140

- 86

- 48

- 8,2

-

OT1 , OT4 - -

Excellent fiber wet-out

- Good mechanical properties

- Optimum HDT

- Low styrene emission

- No sagging on vertical surfaces

- AC units and system components, applications which require mechanical strength such as GRP parts for marine and automotive industry.

-

Polipol 351

- Hand lay-up / Spray-up medium - high reactivity polyester

- Ortho

-

- 600-800

- N/A

- 35-40

- 7-14

- 190

- 66

- 2,2

- 140

- 100

- 45

- 8,7

-

OT1 , OT2 - - High

HDT and mechanical

values

- Fast demolding time

- Food Contact

- GRP parts which require heat resistance..

-

Polipol 351

TA-LSE-H20/H40 - Hand lay-up / Spray-up medium - high reactivity thixotropic preaccelerated LSE polyest

- Ortho

-

- 600-800

- Thixotropic

- 43-47

- (18-22) / (38-42)

- 190

- 65

- 2

- 132

- 104

- 46

- 8,95

-

OT1 , OT4 - - High

HDT and mechanical

values

- Fast demolding time

- Low styrene emission

- No sagging on vertical surfaces

- GRP parts which require heat resistance.

-

Polipol 344-T

- Hand lay-up / Spray-up heat resistant thixotropic polyester

- THPA

-

- 600-800

- Thixotropic

- 40-43

- 10-18

- 190

- 70

- 2,3

- 140

- 115

- 43

- 8,2

-

OT1 , OT2 - -

Excellent HDT and mechanical

properties

- DIN 16946/2: Type 1140

- MAN Nuremberg Lab 3F approved

- GRP parts which require high temperature resistance such as automobile and machinery hood, body and roofs.

-

Polipol 344

TA-LSE - Hand lay-up / Spray-up heat resistant thixotropic preaccelerated LSE polyester

- THPA

-

- 600-800

- Thixotropic

- 40-43

- 10-20

- 190

- 70

- 2,3

- 140

- 115

- 43

- 8,2

-

OT1 , OT4 - -

Excellent HDT and mech. prop.

- DIN 16946/2: Type 1140

- MAN Nuremberg Lab 3F approved

- Low styrene emission

- GRP parts which require high temperature resistance such as automobile and machinery hood, body and roofs.

-

Polipol 3469

TA-LSE-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated LSE polyester

- DCPD

-

- 600-700

- Thixotropic

- 35-38

- (18-22) / (38-42)

- 150

- 70

- 2,46

- 120

- 85

- 44

- 6

-

OT1 , OT4 - -

Special DCPD structure

- High quality part surface

- Excellent fiber wet-out

- Low styrene content

- Low volumetric shrinkage

- Components that require high surface quality especially for commercial vehicles and truck GRP part productions.

-

Polipol 3471

TA-LSE - Hand lay-up / Spray-up high HDT thixotropic preaccelerated LSE polyester

- Ortho

-

- 800-1000

- Thixotropic

- 40-43

- 19-21

- 195

- 72

- 2,4

- 140

- 123

- 50

- 8,2

-

OT1 , OT4 - -

Minimal shape deformation

- Excellent HDT

- DIN 16946/2: Type 1140

- Fast demolding time

- Low styrene emission

- GRP parts which require high temperature resistance such as automobile and engine hood, body and roofs.

-

Polipol 3872

Lloyd's - Chemical resistant polyester

- ISO

-

- 700-800

- N/A

- 37-41

- 15-17

- 190

- 75

- 4,2

- 136

- 93

- 42

- 8,7

-

OT1 , OT2 - -

Chemical resistance (ref CRG)

- Food contact

- Good fiber wetting

- Good mechanical properties

- Lloyd's Register approved

- GRP parts which require flexibility and mechanical strength, linings that require resistance to weak alkaline and acidic environments.

-

Polipol 3872

Lloyd's

TA-LSE-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated LSE polyester

- ISO

-

- 450-600

- Thixotropic

- 40-44

- (18-22) / (35-40

- 190

- 75

- 4,2

- 136

- 93

- 42

- 8,7

-

OT1 , OT4 - - Very

good fiber wet-out

- Chemical resistance against many chemicals. (ref CRG)

- Excellent mechanical values

- Lloyd's Register approved

- GRP parts which require flexibility and mechanical strength, linings that require resistance to weak alkaline and acidic environments.

-

Polipol 3469

TA-H20/H40 - GRP type thixotrpic preaccelerated polyester resin

- DCPD

-

- 600-700

- Thixotropic

- 19-21

- (18-22) / (35-40)

- 130

- 70

- 2,5

- 120

- 85

- 44

- 6,0

-

OT1 , OT4 - -

Special DCPD structure

- High quality part surface

- Excellent fiber wet-out

- Paraffine-Free

- Low volumetric shrinkage

- Components that require high surface quality especially for commercial vehicles , yachts, and truck GRP part productions.

-

Polives 701

Lloyd's - High chemical resistant performance vinyl ester

- VE

-

- 400-500

- N/A

- 40-44

- 20-30

- 175

- 80

- 5,5

- 160

- 100

- 35

- 7,7

-

OT1 , OT5 - -

Excellent chemical resistance

and mechanical properties

- Excellent hydrolytic resistance

- Lloyd's Register approved

- Food Contact

- Composite applications which require hydrolysis resistance, chemical resistance and mechanical strength.

-

Polives 701

Lloyd's

TA-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated performance vinyl ester

- VE

-

- 600-800

- Thixotropic

- 42-44

- (18-22) / (38-42)

- 175

- 80

- 5

- 160

- 100

- 35

- 7,7

-

OT1 , OT6 - - High

hydrolytic and chemical

resistance

- Excellent mechanical properties

- No sagging on vertical surfaces

- Lloyd's Register approved

- Composite applications which require hydrolysis resistance, chemical resistance and mechanical strength.

-

Polives 711

- High chemical resistant high performance vinyl ester

- VE

-

- 300-400

- N/A

- 33-37

- 20-30

- 185

- 80

- 6

- 160

- 115

- 35

- 7,9

-

OT1 , OT5 - - High

HDT

- Excellent hydrolytic and chemical resistance

- Excellent mechanical properties

- Excellent fiber wet-out

- High performance composite applications which require hydrolysis resistance, chemical resistance and mechanical strength.

-

Polives 711-TA

- Hand lay-up / Spray-up thixotropic preaccelerated high performance vinyl ester

- VE

-

- 500-800

- Thixotropic

- 38-41

- (18-22) / (38-42)

- 180

- 80

- 6

- 160

- 115

- 35

- 7,9

-

OT1 , OT6 - - High

HDT

- Excellent hydrolytic and chemical resistance

- Excellent mechanical properties

- No sagging on vertical surfaces

- High performance composite applications which require hydrolysis resistance, chemical resistance and mechanical strength.

-

Polives 710

- Flame retardant epoxy vinyl ester

- VE

-

- 400-500

- N/A

- 34-38

- 20-30

- 185

- 75

- 3

- 165

- 110

- 35

- 7,7

-

OT1 , OT5 - -

Effective flame retardant

properties in combination with

Antimony

- Excellent hydrolytic and chemical resistance

- High performance composite applications which require hydrolysis resistance, chemical resistance, mechanical strength and flame retardancy

-

Polives 710

TA-H20/H40 - Hand lay-up / Spray-up flame retardant thixotropic high performance vinyl ester

- VE

-

- 600-800

- Thixotropic

- 34-36

- (18-22) / (38-42)

- 175

- 70

- 3

- 165

- 105

- 35

- 7,7

-

OT1 , OT6 - - Flame

retardant

- High HDT

- Excellent solvent and chemical resistance

- No sagging on vertical surfaces

- High performance composite applications which require hydrolysis resistance, chemical resistance, mechanical strength and flame retardancy.

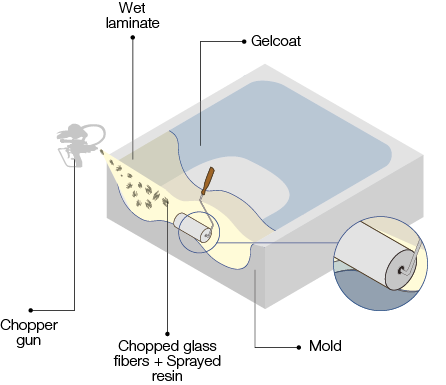

Spray-up Application

Glass fiber roving and catalyzed resins are sprayed on mold surface with a chopper gun. Any air trapped after spraying is released with a roller. Spray-up production steps:

① Apply wax-based release agent on mold surface (ref. mold release waxes)

② Apply gelcoat film with 500-800 micron thickness

③ Check chopper machine pressure and peroxide ratio

④ Spray polyester resin and chopped fibers with spray gun

⑤ Continue spray-up until obtaining desired thickness

⑥ Release trapped air with roller

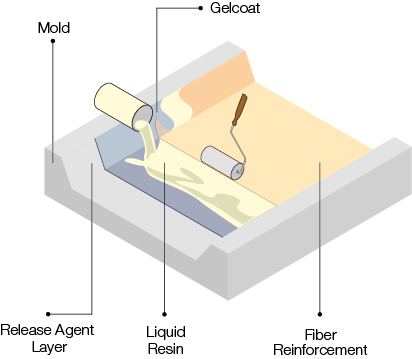

Hand Lay-up Application

Hand lay-up production offers design flexibility, with low cost and provides a good choice for many producers. It is an ideal method for low quantity part manufacturing. Hand lay-up production method allows flexibility with part shapes and lamination design and have lower mold costs compared to other production techniques. Additionally, it is possible to obtain desired mechanical properties with different fiber resin ratios. Hand lay-up production steps:

① Apply mold release agent on mold surface

② Apply 500-800 micron gelcoat film on mold surface

③ After gelcoat has reached a certain cured state, lamination steps can begin

④ Composite part should be trimmed after demolding

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored