It is possible to produce products like kitchen countertops, sinks and trinkets at very low cost. We have industrial type resins for both solid surfaces and standard casting applications. Polipol 3455 and Polipol 353 are used in standard casting applications with high filler capacity. They do not allow twisting and have a high demolding speed. Polipol 3813 and Polipol 383-G have high chemical and UV resistance on solid surfaces.

Barriercoats are a special kind of gelcoat which is applied after the gelcoat layer.

Barriercoats

Barriercoats are a special kind of gelcoat which is applied after the gelcoat layer. They offer high hydrolysis and chemical resistance, prevent fiber print-through and offer high osmosis and blister resistance on finished products. Barriercoats form a solid base layer for gelcoats with their stiffness and mechanical strength. The amount of barriercoat consuption per square meter is lower than gelcoats because of their lower density values.

SONRAKİ

ÖNCEKİ

- Product Description

- Chemical Structure

- Base Color

- Application

-

Pre-Acceleration

-

Viscosity

-

Gel Time

-

Flexural Strength

-

Flexural Modulus

-

Water Absorbtion

- Remarks

- Highlights

- Primary Usages

- Polijel BC

- High hydrolytic resistant barriercoat

- VE

- N/A

-

- Yes

- 1600-2200

- 15-20

- 150

- 3600

- 0,15

-

OT1 , OT6 - -

Excellent hydrolytic and chemical resistance

- No sagging on vertical surfaces

- High surface quality

- High osmosis and blister resistance

- Eleminates fiber print-through and improves osmosis and blistering resistance in marine applications, swimming pools, water slides and parks. It can be applied up to 300-400 microns.

- Polijel BC-782

- High surface performance flexible barriercoat

- VE/ ISO/ NPG

- N/A

-

- Yes

- 3700-4100

- 14-16

- 67

- 2500

- 0,17

-

OT1 , OT24 - -

Flexible

- Low fiber print-through and high surface quality

- High surface quality

- Good surface appearance on finished product

- Specially designed to eleminate fiber print through and improve osmosis and blistering resistance in automotive applications.

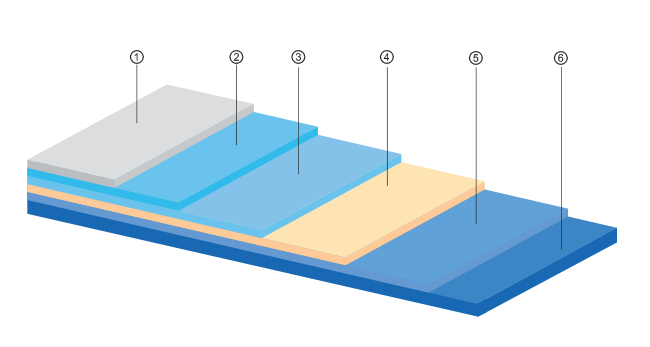

Layers of High Blister and Osmosis Resistant System (for swimming pools and marine applications)

① Polijel 213 High performance clear gelcoat

② Polijel 213 High performance colored gelcoat

③ Polijel BC High hydrolytic resistant barriercoat

④ Polives 701-TA Hand lay-up/Spray-up thixotropic preaccelerated performance vinyl ester

⑤ Polipol 383-TA High chemical resistant thixothropic preaccelerated polyester

⑥Polipol 3401-TA Hand lay-up/Spray-up thixotropic preaccelerated polyester

② Polijel 213 High performance colored gelcoat

③ Polijel BC High hydrolytic resistant barriercoat

④ Polives 701-TA Hand lay-up/Spray-up thixotropic preaccelerated performance vinyl ester

⑤ Polipol 383-TA High chemical resistant thixothropic preaccelerated polyester

⑥Polipol 3401-TA Hand lay-up/Spray-up thixotropic preaccelerated polyester

Previous

Next

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored