Acrylic Backing

Acrylic backing application is used for the reinforcement of acrylic sheets, especially for acrylic bath tubs. Polipol 341-TA-White with 30% or 40% filler (calcite) content has excellent adhesion on acrylic sheets. Polipol 342-TA-D40-White is recommended for ABS sheet backing applications.

Polipol 341-TA-D40-White, used in shower trays and bases, has excellent adhesion to acrylic sheets with very good fiber wet-out.

Acrylic Backing

Acrylic backing application is used for the reinforcement of acrylic sheets, especially for acrylic bath tubs. Polipol 341-TA-White with 30% or 40% filler (calcite) content has excellent adhesion on acrylic sheets. Polipol 342-TA-D40-White is recommended for ABS sheet backing applications.

Bath Tubs

Whirpool / Jacuzzi Tub

Acrylic Backing with Chopper Gun

- Product Description

- Chemical Structure

- Available Modifications

- Viscosity

-

Thixotropy

-

Filler Ratio

-

Gel Time

- Remarks

- Highlights

- Primary Usages

- Polipol 341 TA-White

- Acrylic type thixotropic polyester

- Ortho

-

- 400-500

- Thixotropic

- -

- 10-12

-

OT1 , OT15 - -

Excellent adhesion to acrylic

- Good fiber wet-out

- Mek-P indicator

- Unfilled

- Acrylic bath tub and shower backing..

- Polipol 341 TA-D40-White

- Acrylic type thixotropic preaccelerated filled white polyester

- Ortho

-

- 1000-1200

- Thixotropic

- 40

- 8-12

-

OT1 , OT15 - -

Excellent adhesion to acrylic

- Good fiber wet-out

- Mek-P indicator

- Unfilled

- Acrylic bath tub and shower backing.

- Polipol 342 TA-White

- Acrylic type thixotropic preaccelerated unfilled white polyester

- Ortho

-

- 800-900

- Thixotropic

- -

- 8-12

-

OT1 , OT15 - -

Excellent adhesion to acrylic

- Good fiber wet-out

- Mek-P indicator

- Unfilled

- Acrylic bath tub and shower backing.

- Polipol 342 TA-D40-White

- Acrylic / ABS type thixotropic preaccelerated filled white polyester

- Ortho

-

- 1100-1500

- Thixotropic

- 40

- 12-22

-

OT1 , OT15 - -

Excellent adhesion to acrylic

- Good fiber wet-out

- Mek-P indicator

- Filled

- Acrylic-ABS bath tub and shower backing.

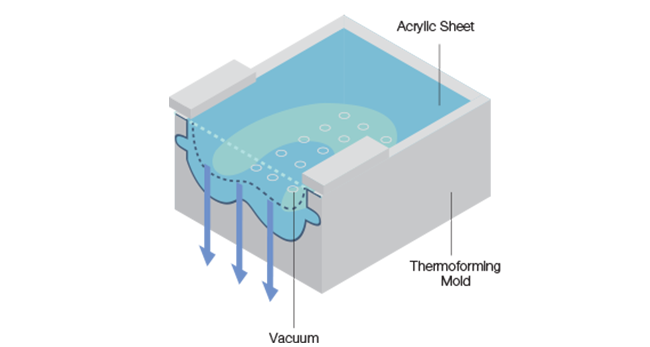

Acrylic Vacuum Forming Application

① Heat acrylic sheet to softening point.

② Mount soft sheet on the mold and apply vacuum pressure to get the desired shape.

③ Demold the sheet and cool down.

Note: In order to have uniform thickness through out the sheet, it is important to have a good mold designed for vacuuming.

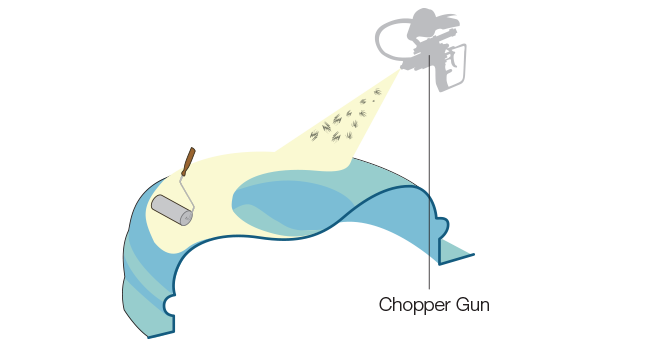

Acrylic Backing Application

① Incorporate desired amount of filler into Polipol 341-TA White and connect to spray up machine.

② Adjust peroxide ratio and pressure of the gun according to application environment.

③ Adjust chopper fiber/resin ratio.

④ Spray catalyzed resin with chopped glassfibers on the sheet.

⑤ It is possible to insert hardboards at this stage if needed.

⑥ Spray more catalyzed resin with chopped glassfibers.

⑦ Release trapped air with the help of a roller and brush.

⑧ Reinforced acrylic sheets are cured in curing oven at temperatures between 40-50°C.

⑨ After curing, trim the edges and mount accessories.

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored