Chemical Resistant Applications

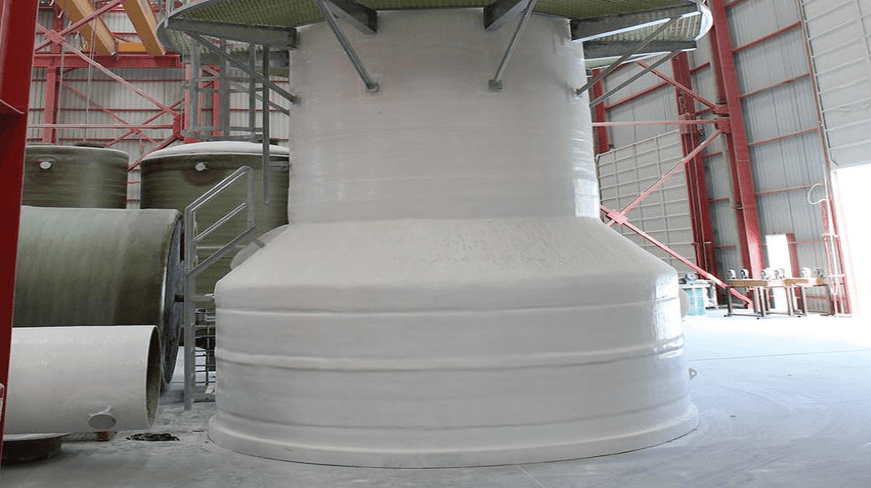

The vinyl ester and polyester resins of this group are specially designed for resistance againsts chemical corrosion and high temperatures. Isophthalic, ISO/NPG, VE, BPA type resins are used in applications where the parts are in direct contact with corrosive materials and good mechanical properties required. Chemical storage tanks, pipes, scrubbers-absorbers, spray banks and recirculators, spools, stack and chimney for petrochemical industries, pulp mills, power plants, marine vehicles, solar panel systems and polyester concrete flooring applications are the main areas of use for this class of products.

Polyesters and vinyl ester are used in applications to protect against acidic, alkaline and corrosive exposure.

Chemical Resistant Applications

The vinyl ester and polyester resins of this group are specially designed for resistance againsts chemical corrosion and high temperatures. Isophthalic, ISO/NPG, VE, BPA type resins are used in applications where the parts are in direct contact with corrosive materials and good mechanical properties required. Chemical storage tanks, pipes, scrubbers-absorbers, spray banks and recirculators, spools, stack and chimney for petrochemical industries, pulp mills, power plants, marine vehicles, solar panel systems and polyester concrete flooring applications are the main areas of use for this class of products.

Chemical Storage

Underground Chemical Container

Corrosive Air Flow Ducting and Venting

Fittings

Cooling Towers

Electrolysis Vessels

- Product Description

- Chemical Structure

-

Available Modifications

-

Viscosity

-

Monomer Content

-

Acid Value

-

Gel Time

-

Tensile Strength

-

Elongation at Break, Tensile

-

Flexural Strength

-

HDT [0,45 MPa]

-

Barcol Hardness, 934

-

Volumetric Shrink

- Remarks

- Highlights

- Primary Usages

-

Polipol 3872

Lloyd's - Chemical resistant polyester

- ISO

-

- 700-800

- 36-39

- max. 14

- 15-17

- 75

- 4,2

- 136

- 93

- 42

- 8,7

-

OT1 , OT2 - -

Chemical resistant (ref CRG)

- Good fiber wet-out

- Good mechanical properties

- Lloyd's register approved

- Food contact

- Lining of tanks which hold weak acids and alkalines, olives storage tanks, production of GRP tanks. Ideal for hygienic food contact surfaces.

-

Polipol 381

Lloyd's - High chemical resistant polyester

- ISO/NPG

-

- 600-800

- 36-39

- max. 15

- 8-12

- 68

- 2,6

- 124

- 101

- 48

- 8,1

-

OT1 , OT2 - -

High chemical and UV resist.

- Good mechanical properties

- Special ISO/NPG structure

- Food contact

- Adhesion PVC

- Lloyd's Register Approved

- Medium high corrosivity GRP storage tanks, electrolysis cups, treatment pool. Ideal for hygienic food contact surfaces.

-

Polipol 391

- High thermal and chemical resistant bisphenolic polyester

- BPA

-

- 600-800

- 44-48

- max. 14

- 9-13

- 50

- 2,1

- 133

- 129

- 43

- 7,47

-

OT1 , OT16 - -

Excellent chemical resistance

- High thermal resistance

- Special BPA structure

- GRP applications which require high chemical resistance against acids and corrosive environments such as chemical plants, and electrolysis cups.

-

Polives 701

Lloyd's - High chemical resistant performance vinyl ester

- VE

-

- 400-500

- 40-44

- max. 10

- 20-30

- 80

- 5

- 160

- 100

- 35

- 7,7

-

OT1 , OT5 - -

Excellent chemical and

mechanical resistance

- Excellent hydrolitic resistance

- Lloyd's Register approved

- Food contact

- GRP applications which require high chemical resistance against acids and corrosive environments such as chemical plants and electrolysis cups. Ideal for food contact surfaces.

-

Polives 711

- High chemical resistant high performance vinyl ester

- VE

-

- 300-400

- 33-37

- max. 12

- 20-30

- 80

- 6

- 160

- 115

- 35

- 7,9

-

OT1 , OT5 - -

High HDT

- Excellent hydrolytic and chemical resistance

- Excellent mechanical properties

- Excellent fiber wet-out

- GRP applications which require high chemical resistance against acids and corrosive environments such as chemical plants, and electrolysis cups.

-

Polives 710

- Flame retardant epoxy vinyl ester

- VE

-

- 400-500

- 34-38

- max. 10

- 20-30

- 75

- 3

- 165

- 110

- 35

- 7,7

-

OT1 , OT5 - -

High flame retardency with

antimony

- High hydrolytic and chemical resistance

- Excellent fiber wet-out

- Halogenated

- High chemical resistant and flame retardant applications such as boiler units, engine insulation, pipelines and chemical storage tanks, process and storage tanks and yachts.

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored