Filament Winding

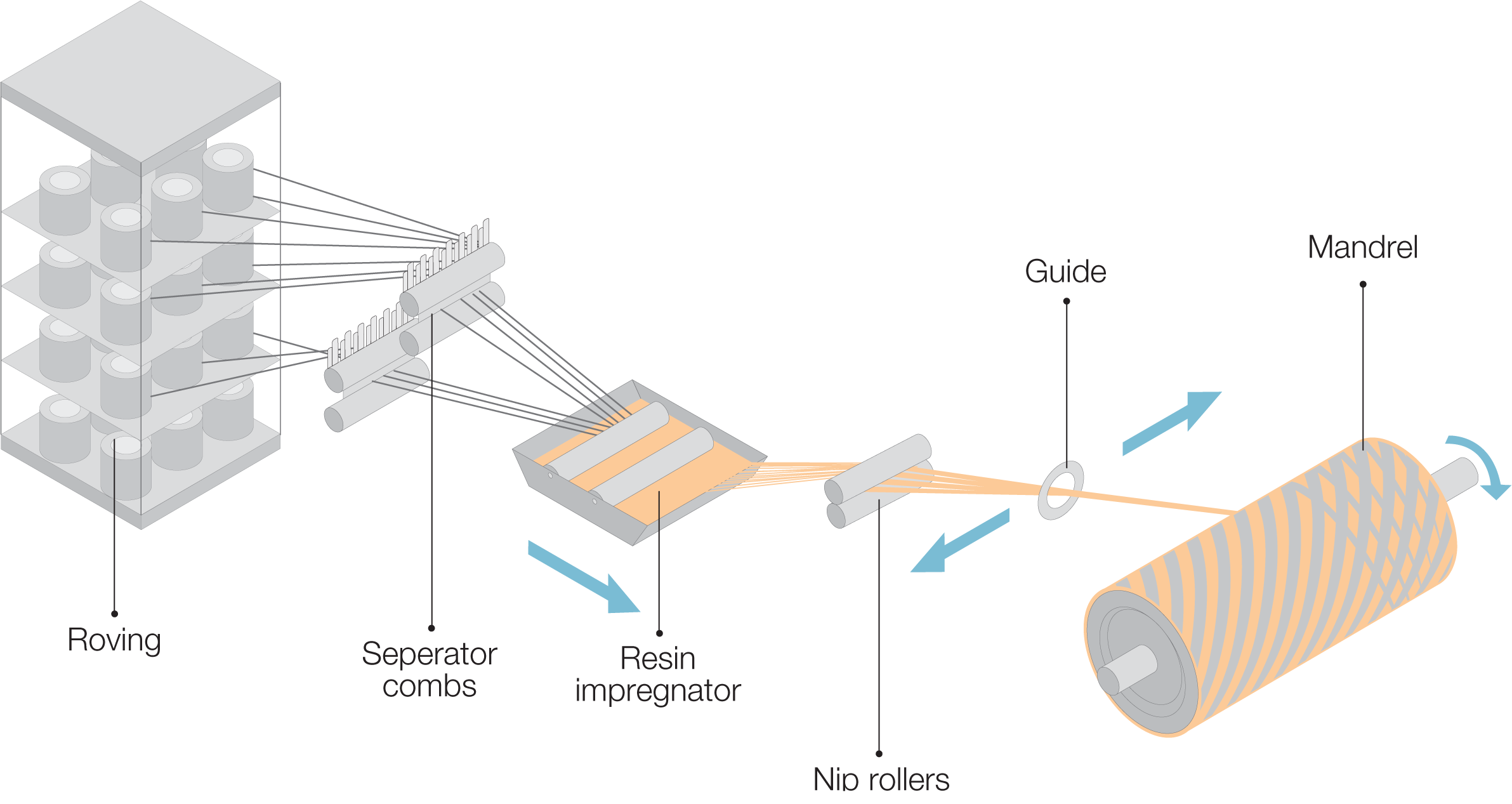

Filament winding is an ideal production method for producing cylindrical structures. Filament winding process has two different types. (A) Helical Filament Winding (B) Continuous Filament Winding. Fiberglass and catalyzed resin are wound over a rotating mandrel. Composite tanks, silos, ducts, water tanks, pipes and pressurized vessels are produced with this method. Polipol 3562 has high mechanical properties and good fiber wet-out. Polipol 3872-I is the preferred choice where high elongation at breaking point and chemical resistance is needed.

Filament winding is an ideal method for producing cylindrical structures.

Filament Winding

Filament winding is an ideal production method for producing cylindrical structures. Filament winding process has two different types. (A) Helical Filament Winding (B) Continuous Filament Winding. Fiberglass and catalyzed resin are wound over a rotating mandrel. Composite tanks, silos, ducts, water tanks, pipes and pressurized vessels are produced with this method. Polipol 3562 has high mechanical properties and good fiber wet-out. Polipol 3872-I is the preferred choice where high elongation at breaking point and chemical resistance is needed.

Chemical Resistant Lines

Fittings and Joints

Tank and Silo Production

Irrigation Pipes

Irrigation Pipelines

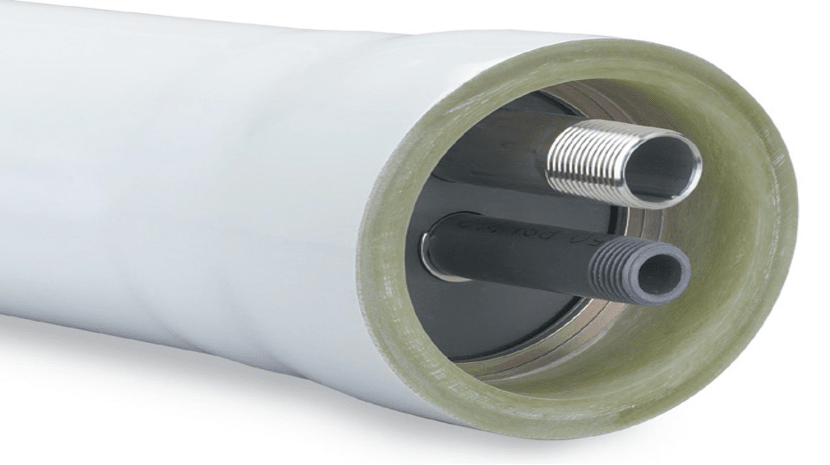

Pressurized Vessels and Tubes

- Product Description

- Chemical Structure

- Available Modifications

- Viscosity

-

Monomer Content

-

Acid Value

-

Gel Time

-

Tensile Strength

-

Elongation at Break, Tensile

-

Flexural Strength

-

HDT [0,45 MPa]

-

Barcol Hardness, 934

- Remarks

- Highlights

- Primary Usages

-

Polipol 3562

- Filament winding type polyester

- Ortho

-

- 250-350

- 38-43

- max. 22

- 14-16

- 74

- 3,15

- 125

- 75

- 42

-

OT1 , OT10 - -

High mechanical properties

- Special formulation for pipe producers

- Good fiber wet-out

- High modulus of elasticity

- Tanks, silos, GRP pipes.

-

Polipol 3872-I

- Chemical resistant polyester

- ISO

-

- 370-420

- 39-43

- max. 12

- 6-14

- 76

- 4,2

- 140

- 97

- 44

-

OT1 , OT9 - -

Chemical resistant

- High elongation at breaking point

- Good fiber wet-out

- Food contact

- GRP pipes, equipment production for the chemical industry, storage and transfer units.

-

Polipol 3570

New - Filament winding type polyester

- rPET

-

- 200-300

- 43-46

- max. 18

- 10-20

- 71

- 3,2

- 129

- 86

- 46

-

OT1 , OT10 - -

High mechanical properties

- Recycle pet based

- Good fiber wet-out

- High modulus of elasticity

- Tanks, silos, GRP pipes.

-

Polipol 3880

- Terephthalic polyester

- Terephtalic

-

- 600-800

- 37-41

- max. 16

- 14-16

- 70

- 3,9

- 135

- 102

- 48

-

OT1 , OT2 - -

High HDT value

- Excellent mechanical and thermal values

- High modulus and elongation at break value

- Tanks, silos, GRP pipes.

Helical Filament Winding Application

Fibers are wetted in the resin bath.After the resin bath, fibers are wound around a constant length rotating steel mandrel. Angular winding in a longitudinal direction will provide more strength. With this method, production of consistent size pipes are possible.

A polyester based release film is applied on the mandrel and a chemical resistant layer will form the first layer. Continuous fiberglass is applied for structural integrity. These composite materials contain no or low filler. This provides a lighter product but at a higher cost. This type of production is usually preferred for chemical process equipment and pressurized vessels.

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored