Low Styrene Emission / LSE

Styrene evaporation in hand lay-up and spray-up production may cause VOC emission problems in the work environment. The low styrene content and low styrene emission resins in this product group offer a safer working environment for workers by lowering the amount of styrene evaporation.

LSE type resins suppress the styrene evaporation and provide for a safer environment.

Low Styrene Emission / LSE

Styrene evaporation in hand lay-up and spray-up production may cause VOC emission problems in the work environment. The low styrene content and low styrene emission resins in this product group offer a safer working environment for workers by lowering the amount of styrene evaporation.

GRP parts

Yachts and Boats

AC Vents and Ducts

- Product Description

- Chemical Structure

-

Available Modifications

-

Viscosity

-

Thixotropy

-

Monomer Content

-

Gel Time

-

Tmax

-

Tensile Strength

-

Elongation at Break, Tensile

-

Flexural Strength

-

HDT [0,45 MPa]

-

Barcol Hardness, 934

-

Volumetric Shrink

- Remarks

- Highlights

- Primary Usages

-

Polipol 3401

Lloyd's

TA-LSE-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated LSE polyester

- Ortho

-

- 500-600

- Thixotropic

- 43-47

- (18-22) / (38-42)

- 140

- 71

- 2,6

- 134

- 66

- 40

- 7,4

-

OT1 , OT4 - -

Low styrene emission

- No sagging on vertical surfaces

- Quick and easy fiber wet-out

- Lloyd's Register approved

- Bumpers, fenders, cabinets, pool filters and industrial GRP parts such as vehicle parts.

-

Polipol 339

TA-LSE-H20/H40 - Hand lay-up / Spray-up medium reactivity thixotropic preaccelerated LSE polyester

- Ortho

-

- 600-800

- Thixotropic

- 41-44

- (18-22) / (38-42)

- 180

- 68

- 2,2

- 140

- 86

- 48

- 8,2

-

OT1 , OT4 - -

Excellent fiber wet-out

- Good mechanical properties

- Optimum HDT

- Low styrene emission

- No sagging on vertical surfaces

- AC units and system components, applications which require mechanical strength such as GRP parts for marine and automotive industry.

-

Polipol 3381

New

TA-LSE-H20/H40 - High temperature resistant ISO, thixotropic preaccelerated LSE poliester

- ISO

-

- 600-800

- Thixotropic

- 43-47

- (18-22) / (38-42)

- -

- 70

- 2,2

- 140

- 118

- 30

- 8,0

-

OT1 , OT4 - -

Minimal shape deformaiton

- Excellent HDT

- Fast demolding time

- Low styrene emission

- GRP parts which require thermal resistance such as vehicle and machinery hoods and engine components.

-

Polipol 351

TA-LSE-H40 - Hand lay-up / Spray-up medium/high reactivity thixotropic preaccelerated LSE polyester

- Ortho

-

- 600-800

- Thixotropic

- 41-44

- 38-42

- 190

- 65

- 2

- 132

- 104

- 46

- 8,95

-

OT1 , OT4 - -

High HDT and mechanical

values

- Fast demolding

- Low styrene emission

- Low styrene emission

- Industrial GRP parts which require thermal resistance.

-

Polipol 3471

TA-LSE-H20/H40 - Hand lay-up / Spray- up high HDT thixotropic preaccelerated LSE polyester

- Ortho

-

- 800-1000

- Thixotropic

- 40-43

- (18-22) / (38-42)

- 195

- 72

- 2,4

- 140

- 123

- 50

- 8,2

-

OT1 , OT4 - -

Minimal shape deformaiton

- Excellent HDT

- Fast demolding time

- Lloyd's Low styrene emission

- GRP parts which require thermal resistance such as vehicle and machinery hoods and engine components.

-

Polipol 3872

Lloyd's

TA-LSE-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated LSE polyester

- ISO

-

- 450-600

- Thixotropic

- 40-44

- (18-22) / (38-42)

- 190

- 75

- 4,2

- 136

- 93

- 42

- 42

-

OT1 , OT4 - -

Chemical resistant

- Good fiber wet-out

- Good mechanical properties

- No sagging on vertical surfaces

- Lloyd's Register approved

- GRP parts with high flexibility and mechanical strength requirements, and lining against weak alkaline and acidic environments.

-

Polipol 344

TA-LSE-H20/H40 - Hand lay-up / Spray-up medium/high reactivity thixotropic preaccelerated LSE polyester

- THPA

-

- 600-800

- Thixotropic

- 40-43

- (18-22) / (38-42)

- 190

- 70

- 2,3

- 140

- 115

- 43

- 8,2

-

OT1 , OT4 - -

MAN Nuremberg Lab

3F approved

- Excellent HDT and mechanical properties

- DIN 16946/2: Type 1140

- GRP parts which require thermal resistance such as vehicle and machinery hoods and engine components.

-

Polipol 3469

TA-LSE-H20/H40 - Hand lay-up / Spray-up thixotropic preaccelerated LSE polyester

- DCPD

-

- 600-700

- Thixotropic

- 35-38

- (18-22) / (38-42)

- 150

- 70

- 2,46

- 120

- 85

- 44

- 6

-

OT1 , OT4 - -

Special DCPD structure

- High quality surface

- Excellent fiber wet-out

- Low styrene emission

- Low volumetric shrinkage

- Components that require high surface quality especially for commercial vehicles and truck GRP part productions.

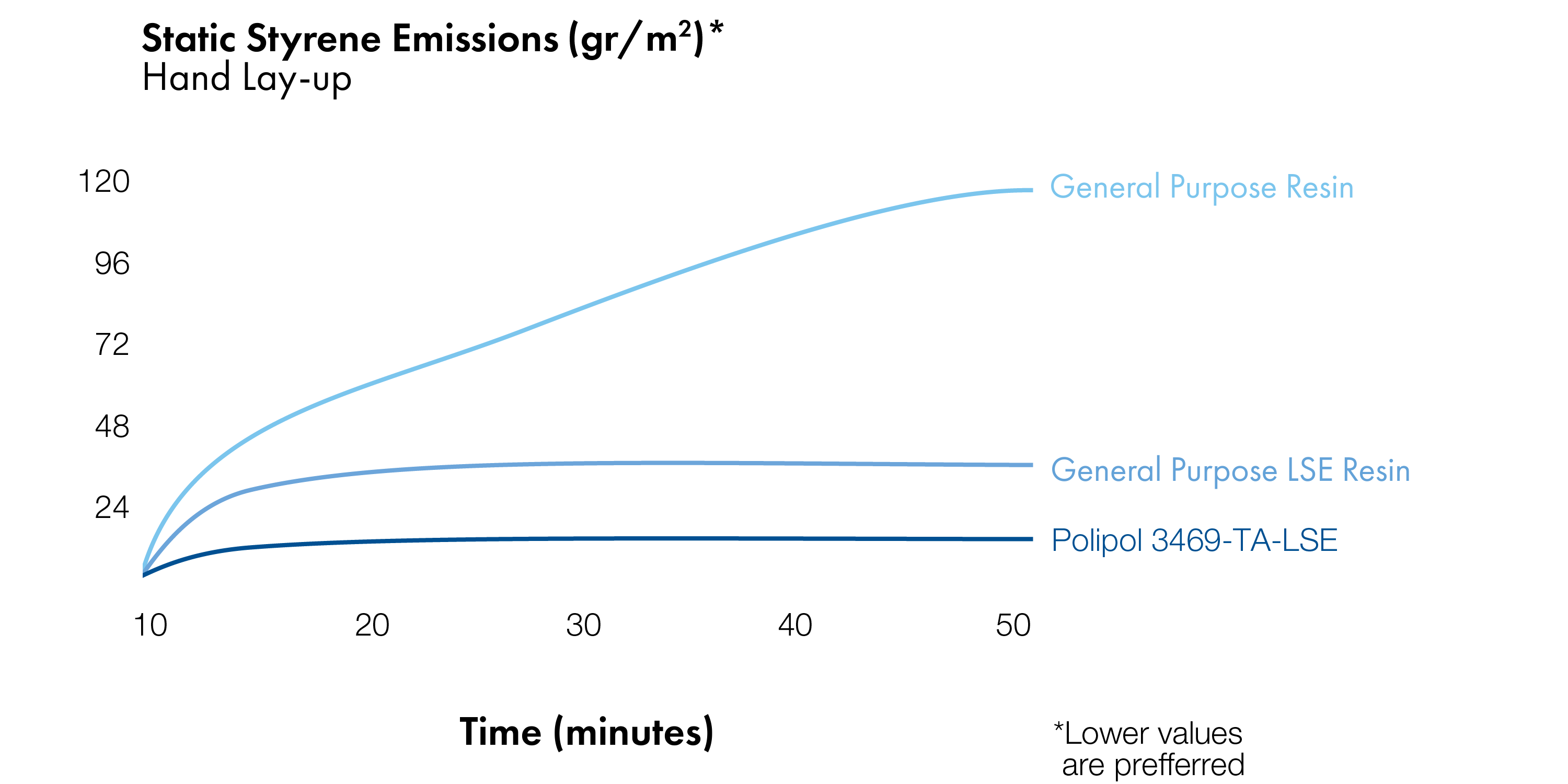

Static Styrene Emission

• Special DCPD structure

• Good part surface

• Excellent fiber wet-out

• Low volumetric shrinkage

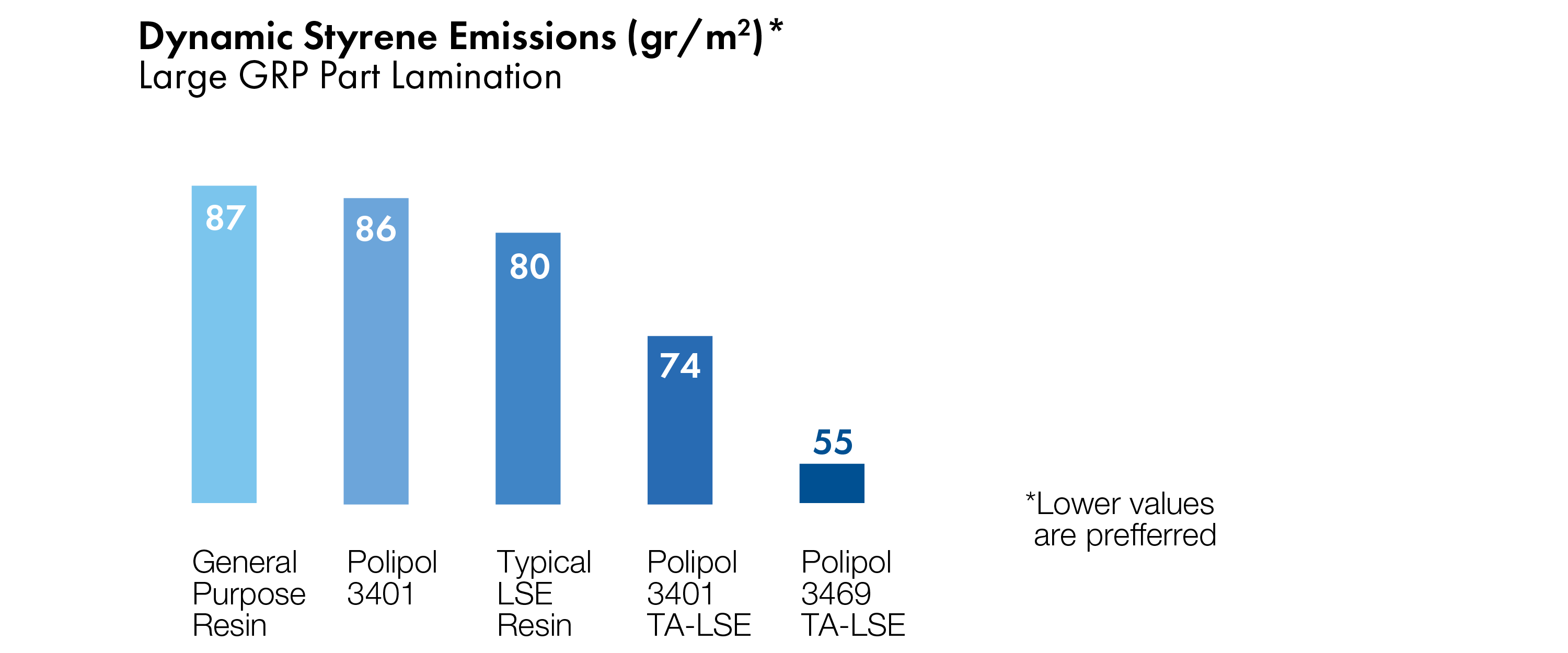

Dynamic Styrene Emissinon

Thixotropic type resins are preferred in GRP applications on vertical surfaces.

These next generation LSE (Lower Styrene Emission) type resins offer healthier working environment for hand lay-up productions.

Polipol 3469-TA-LSE is a new resin with low styrene content and low styrene emission which is suitable for applications on large surfaces. DCPD structure also offers better fiber wet-out.

High HDT Polipol 344-TA-LSE

• Quick and easy fiber wet-out

• High mechanical and thermal properties

• Thixotropic, no sagging on vertical surfaces

• No local heat build up because of resin accumulation

• MAN Nuremberg Lab 3F approved

• DIN 16946/2: Type 1140

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored