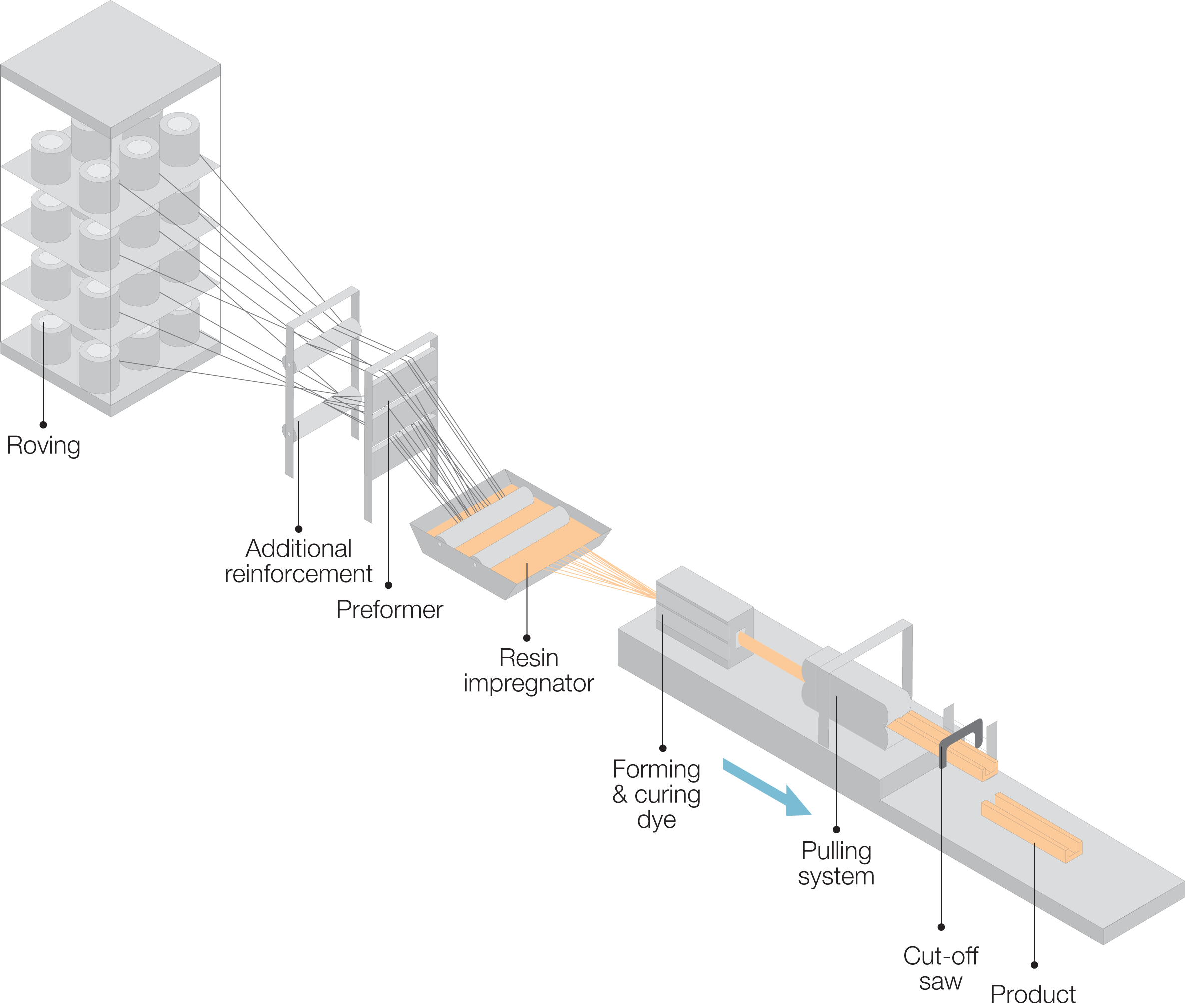

Pultrusion

Pultrusion is a continous method preferred in production of materials with specific mechanical properties in one direction. For example, structural profiles, rebars, posts and pipes of low diameter are produced with this production method. Polipol 3801, with its high reactivity and chemical resistance is preferred for production of gratings and structural profiles. Polives 711 is preferred for production of rebars and profiles. Polipol 3872 is used in road side delineator posts.

It is possible to produce unidirectional, rigid products with glassfiber ratios up to 70%.

Pultrusion

Pultrusion is a continous method preferred in production of materials with specific mechanical properties in one direction. For example, structural profiles, rebars, posts and pipes of low diameter are produced with this production method. Polipol 3801, with its high reactivity and chemical resistance is preferred for production of gratings and structural profiles. Polives 711 is preferred for production of rebars and profiles. Polipol 3872 is used in road side delineator posts.

4G LTE infrastructure with GRP radomes

Construction Beam Profiles

GRP Rebar

Corrosion Repair Components

Delineator Posts

- Product Description

- Chemical Structure

- Available Modifications

- Viscosity

-

Monomer Content

-

Acid Value

-

Gel Time

-

Tensile Strength

-

Elongation at Break, Tensile

-

Flexural Strength

-

HDT [0,45 MPa]

-

Barcol Hardness, 934

- Remarks

- Highlights

- Primary Usages

-

Polipol 351-I

- Medium / High reactivity polyester

- Ortho

-

- 450-550

- 39-42

- max. 22

- 9-11

- 68

- 2,1

- 140

- 103

- 45

-

OT1 , OT8 - -

Good fiber wet-out

- High HDT

- Medium viscosity

- Grating, profiles and industrial pultrusion productions.

-

Polipol 3872-I

- Chemical resistant polyester

- ISO

-

- 370-420

- 39-43

- max. 12

- 6-14

- 76

- 4,2

- 140

- 97

- 44

-

OT1 , OT9 - -

Chemical resistant

- High elongation at breaking point

- Good fiber wetting

- Grating, profiles, and industrial pultrusion applications with a need for chemical resistance.

-

Polipol 3869-I

- SPultrusion type high reactivity chemical resistant polyester

- ISO

-

- 400-450

- 39-43

- max. 13

- 25-30

- 72

- 3,1

- 135

- 108

- 48

-

OT1 , OT2 - -

High reactivity

- Chemical resistant

- Serial production

- High HDT

- High heat resistant pultrusion profiles.

-

Polipol 3801

- SPultrusion type high HDT chemical resistant polyester

- ISO

-

- 600-800

- 37-41

- max. 18

- 7-12

- 62

- 2,6

- 128

- 121

- 40

-

OT1 , OT2 - -

High reactivity

- Chemical resistant

- High HDT

- Equipment production for the chemical industry, rebar and corrosive chemical storage tanks.

-

Polipol 3880

- Terephtalic based polyester

- Terephtalic

-

- 600-800

- 37-41

- max. 16

- 14-16

- 70

- 2,9

- 135

- 102

- 48

-

OT1 , OT2 - - High

HDT value

- Excellent mechanical and thermal values

- High modulus and elongation at break value

- Grating, profiles and industrial pultrusion productions.

-

Polives 709

- Pultrusion type vinyl ester

- VE

-

- 430-480

- 38-41

- max. 10

- 18-22

- 78

- 6

- 155

- 115

- 35

-

OT1 , OT5 - -

Chemical resistance against

many common chemicals

- Very good mechanical values, and high HDT

- A special pultrusion type resin for all kinds of composite applications which require high mechanical values, hydrolytic and chemical resistance

-

Polives 711

- High chemical resistant high performance vinyl ester

- VE

-

- 300-400

- 33-37

- max. 12

- 20-30

- 80

- 6

- 160

- 115

- 35

-

OT1 , OT5 - - High

HDT

- Excellent hydrolytic and chemical resistance

-Excellent mechanical properties

- Excellent fiber wet-out

- Infusion, military and marine applications, wind turbine blades production, composite applications which require hydrolysis resistance, chemical resistance and mechanical strength.

-

Polipol 3878

New - Flame retardant pultrusion type polyester

- ISO/HET

- 400-500

- 37-40

- max. 20

- 12-14

- 83

- 3,2

- 113

- 85

- 42

-

OT1 , OT2 - -

Flame retardant

- Good mechanical properties

- Good fier wet-out

- A special pultrusion type resin for all kinds of composite applications which requires flame retardacy

Pultrusion Application

① Prepare a resin mixture with peroxide, internal release agent and filler.

② Impregnate glass fiber roving in the resin mixture in resin bath.

③ Guide impregnated glass fiber into the heated mold. Mold temperature should be adjusted to specific temperature values upon entrance (40 70°C), inside (80-110°C) and exit (140 170°C).

④ After the heating, the cured and molded profile is cut to specified dimensions.

Note: A high reactivity peroxide (percarbonates) called “kicker” is recommended in cooperation with a perester or perketal based peroxide which finishes the curing reaction.

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored