SMC and BMC Hot Press

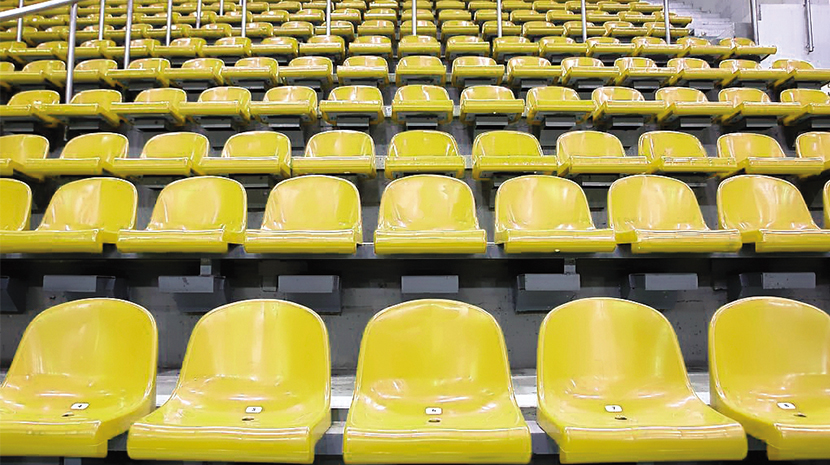

Hot press is a production method that provides, producing composite parts from different molding compound formulations under pressure. It is preferred in high quantity productions because of high investment costs. The following products are under this product range: Polipol 347 for production of park equipment, boxes, recycle bins; Polipol 3417-V for production of high surface quality vehicle parts, composite boxes and cases; Polipol 382 for production of high thermal resistant and chemical resistant composite parts. Polipol 3418 all maleic resin is used in applications where both high surface quality and thermal resistance are needed.

SMC-BMC production methods are one of the fastest production methods for producing composite parts.

SMC and BMC Hot Press

Hot press is a production method that provides, producing composite parts from different molding compound formulations under pressure. It is preferred in high quantity productions because of high investment costs. The following products are under this product range: Polipol 347 for production of park equipment, boxes, recycle bins; Polipol 3417-V for production of high surface quality vehicle parts, composite boxes and cases; Polipol 382 for production of high thermal resistant and chemical resistant composite parts. Polipol 3418 all maleic resin is used in applications where both high surface quality and thermal resistance are needed.

Engine Covers

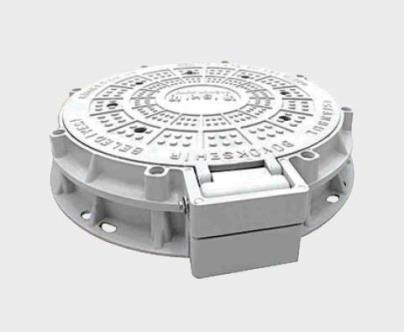

Sewer Manholes

Electrical Boxes and Underground Enclosures

Service Trays

Bulk Molding Compound Dough

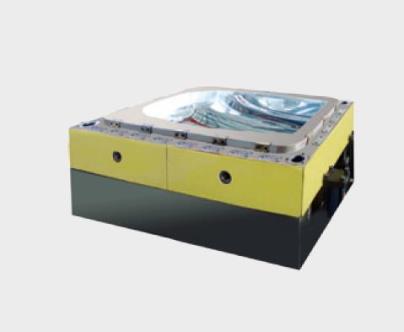

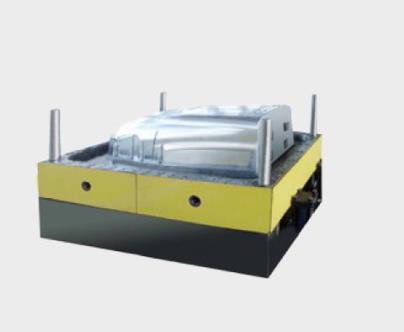

SMC Mold

SMC Mold Inner Surface

Class A Surface Quality

- Product Description

- Chemical Structure

- Available Modifications

- Color

- Viscosity

-

Monomer Content

-

Acid Value

-

Gel Time

-

Flexural Strength

-

Elongation at Break, Tensile

-

HDT [0,45 MPa]

-

Barcol Hardness, 934

- Remarks

- Highlights

- Primary Usages

- Polipol 347

- SMC-BMC type polyester

- Ortho

-

- max. 150

- 800-1100

- 35-38

- max. 28

- 17-24

- 117

- 2,12

- 121

- 49

-

OT1 , OT8 - -

High reactivity

- Stable thickening behavior

- Optimum price performance ratio

- Natural gas boxes, electrical distribution boards and boxes, manhole covers and machine equipment.

- Polipol 3417-V

- SMC-BMC type high surface quality polyester

- Ortho

-

- max. 300

- 1300-1500

- 35-38

- max. 25

- N/A

- 95

- 2,8

- 136

- 49

-

OT1 , OT8 - -

High reactivity

- Stable thickening behavior

- Excellent compability with thermoplastic additives

- Automotive and machine equipment.

- Polipol 382

- SMC-BMC type high chemical resistant polyester

- ISO/NPG

-

- max. 250

- 1200-1600

- 36-40

- max. 16

- 10-13

- 99

- 3

- 144

- 50

-

OT1 , OT2 - -

High chemical resistance

- Excellent HDT

- High reactivity

- DMC

- Electricity isolators, service trays, chemical and high temperature resistant SMC-BMC parts.

- Polipol 3418

- SMC-BMC type all maleic polyester

- MA

-

- max. 150

- 1500-2000

- 34-36

- max. 20

- N/A

- 94

- 1,7

- 135 (1.82 MPa)

- 50

-

OT1 , OT8 - -

All maleic resin

- Excellent HDT

- Excellent compability with thermoplastic additives

- High temperature resistant applications with high surface quality for automotive and machine equipment SMC-BMC parts.

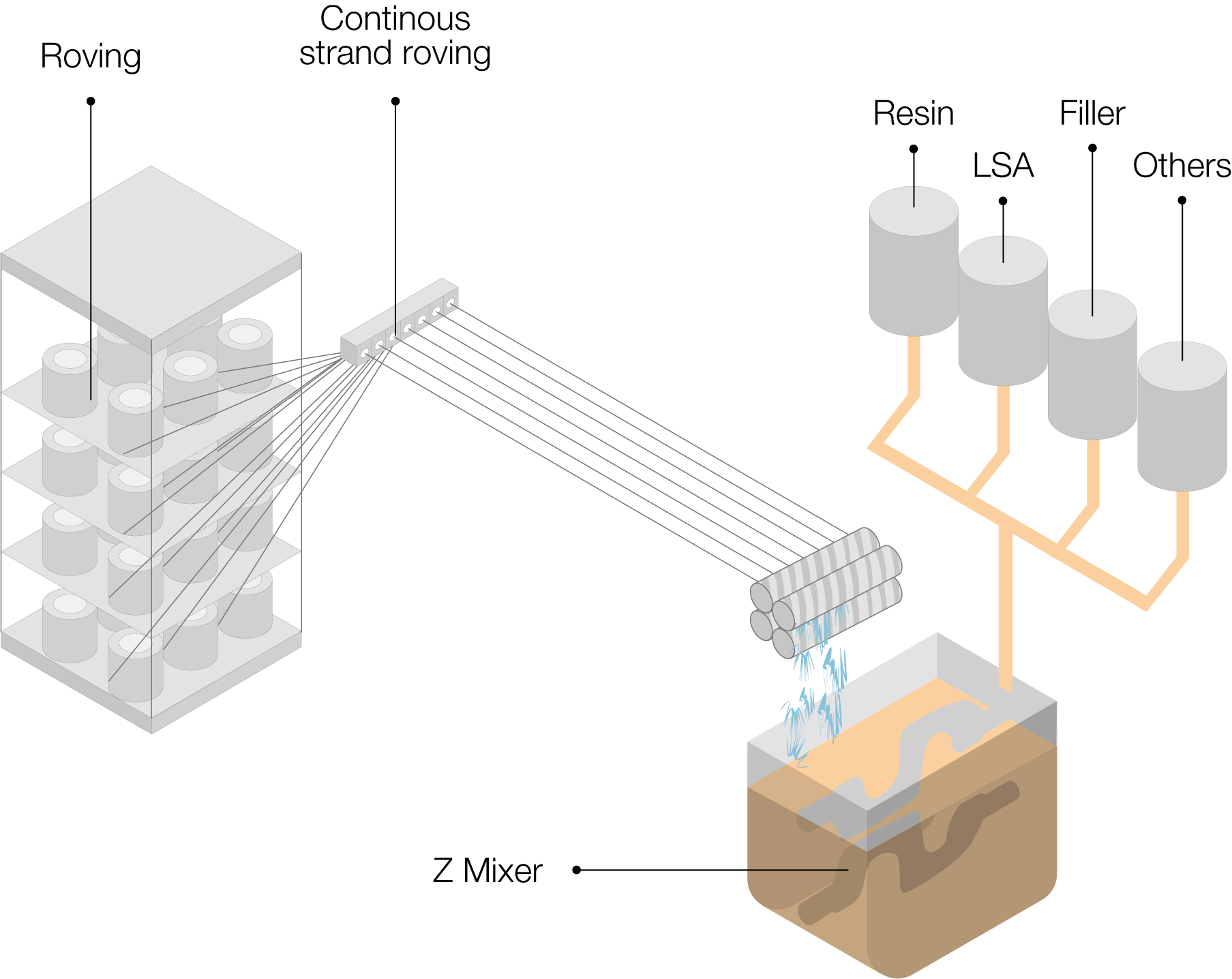

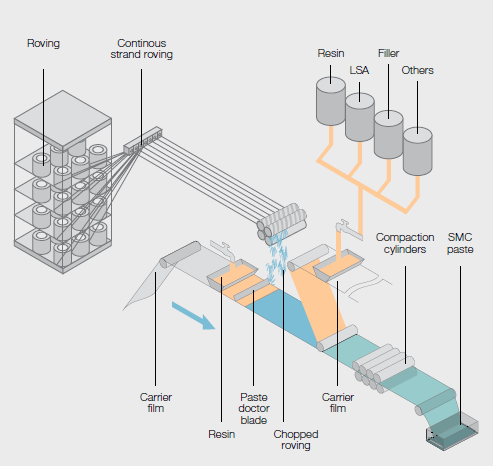

SMC-BMC Paste Production

① Prepare the mixture of Polipol resin, peroxide, thickening agent MgO, filler, thermoplastic additives, pigment paste and internal release agent.

② Transfer resin mixture to the carrier film. Chop glassfiber and sprinkle it onto the resin mixture.

③ Apply second layer of resin mixture to second carrier film.

④ Apply second carrier film on top.

⑤ Press the compound between two carrier films and roll up for maturation for at least two days at 20-23°C.

Note: Temperature has an influence on maturation speed. Maturation will be slower at lower temperatures. For higher mechanical properties, different glassfiber alternatives can be used.

BMC Dough Production

① Prepare the mixture of Polipol resin, peroxide, thickening agent MgO, filler, thermoplastic additives, pigment paste and internal release agent.

② Transfer resin mixture to the carrier film. Chop glassfiber and sprinkle it onto the resin mixture.

③ Apply second layer of resin mixture to second carrier film.

④ Apply second carrier film on top.

⑤ Press the compound between two carrier films and roll up for maturation for at least two days at 20-23°C.

Note: Temperature has an influence on maturation speed. Maturation will be slower at lower temperatures. For higher mechanical properties, different glassfiber alternatives can be used

.

SMC Hot Press Application

① Release the plastic films from the matured compound.

② Place the compound into the hot mold at temperatures between 130-170°C .

③ Ideal molding pressure should be around 150-170 kg/cm2. Molding should take 1minute for every 1mm of material thickness.

④ After molding, demold the product and trim edges.

Packing Types

You can choose any package type suitable for your production system or you can get further information from our sales department regarding container options.

Modification Description

- FR Filled flame retardant

- D* Filled (*with filler content)

- T

Thixotropic (no sagging)

- A

Cobalt preaccelerated

- ABP

Amine preaccelerated

- UV

UV Curing

- L UV light stabilized

- I

Lower viscosity

- V

Higher viscosity

- LSE LSE (low styrene emission)

- H*

Gel time customized (at room temperature) * minutes

H40

Optimized for summer season. Gel time (at room temperature) 40 minutes.

H20

Optimized for winter season. Gel time (at room temperature) 20 minutes.

- COLOR White or custom color options

Gelcoat Customizations

Polijel gelcoat table descriptions and modifications.

Spray Application (airless preferred)

Brush or Roller Application

Color Option: White colored

Color Option: Light colored (pastel)

Color Option: PRO colored